High vacuum atmosphere muffle furnace

Release time: 2022-12-29 10:40:36 Number of views: 820

Equipment introduction:

The stainless steel vacuum chamber of NOBODY High vacuum box furnace is placed in the heated furnace, and the vertical and horizontal reinforcement design and the integrated sealing structure of the furnace can fully guarantee the strength and sealing effect of the stainless steel chamber under high temperature and high vacuum, and the vacuum degree of the equipment can reach 10Pa or less.

This equipment is widely used in tungsten carbide, ceramics, powder metallurgy and other materials in the rough vacuum state, reducing atmosphere, protective atmosphere heat treatment. In addition, the touch screen control system independently developed by our company can improve work efficiency. The furnace can be customized according to the actual needs of users.

Configuration

| 1. The double-layer water cooling structure greatly reduces the surface temperature of the shell; | ||

Model | NBD-VA1100-40T1 | ||

Electrical Spec | ~380V 50HZ | ||

System vacuum | 10pa | ||

Temp Accuracy | ±1℃ | ||

Rated power | 20 KW | ||

Tmax | 1100℃ | ||

| Inner chamber dimensions | L370*H370*D460mm | ||

| Chamber volume | 60L | ||

| Dimensions | L1600×D1100×H1800mm | ||

| Heating rate | ≤20℃/min | ||

Control system |

| 1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |

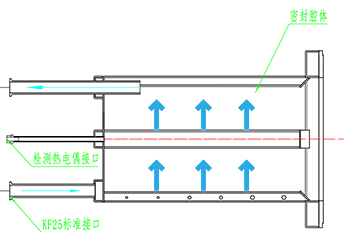

| Schematic diagram of gas circulation |

| ||

| Double layer working chamber design |  |  | |

Net weight | Approx.450KG | ||

Cautions | 1. When the furnace temperature of the equipment is ≥300℃, do not open the furnace to avoid damage; | ||

Service | 1 year warranty with lifetime support (warranty does not include consumable parts) | ||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

Three temperature zone vertical tube furnace (fluidized bed FBCVD furnace)

Vertical quenching furnace

25 station vacuum atmosphere tube furnace

well-type furnace G1700-300TI

CVD system O1200-XTID3F

High Flux Intelligent Chamber Furnace

High temperature vertical rapid pyrolysis furnace

Rotary microwave heating furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China