Thermogravimetric analysis (TGA) and condensation collection systems

Release time: 2022-12-19 09:58:21 Number of views: 629

Equipment introduction:

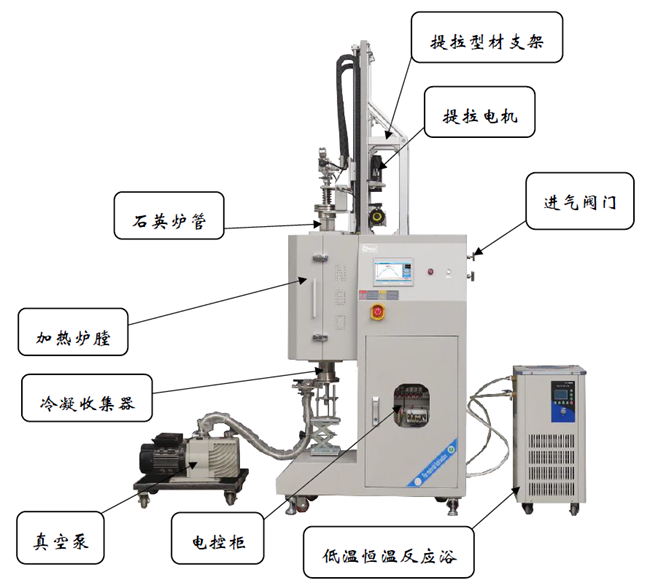

This product was developed for the analysis of the weight loss and pyrolysis weight (TGA) of materials during combustion in a vacuum or atmosphere. It includes balance, heating furnace, programmed temperature control system, recording system and other parts, which can observe the change of sample quality with temperature, time, vacuum degree and atmosphere state in the process of heating, constant temperature or cooling, and is equipped with a condensation collection device for pyrolytic substances. Widely used in plastics, rubber, coatings, drugs, catalysts, inorganic materials, metal materials and composite materials and other fields of research and development, process optimization and quality control.

Configuration

| Equipment introduction:

| ||||||

Model | NBD-TGA1100-80TD2ZY5L | ||||||

main function | 1. In the process of heating, constant temperature or cooling, the quality of the sample can be automatically recorded with the change curve of temperature, vacuum, gas flow and time; | ||||||

Electrical Spec | AC220V 4.5KW | ||||||

Tmax | 1150 ℃ | ||||||

Temp Accuracy | ±1℃ | ||||||

thermocouple | Type K thermocouple 420mm | ||||||

heating-zone size | φ150*430mm single heating-zone dual control | ||||||

Furnace tube material | 310s Stainless steel tube/quartz (interchangeable) | ||||||

| Load cell range | 300g | ||||||

| precision | Within 0.03g | ||||||

| Weight of wire and crucible | Approx.30g | ||||||

| Crucible material&size | Aluminum/stainless steel φ60*30mm | ||||||

| The sample can be weighed | 0~270g | ||||||

| Condensing collector volume and height adjustable range | 110ml can be moved up and down 60mm | ||||||

| Low temperature constant temperature reaction bath temperature control accuracy | ±1 degree volume 6L | ||||||

| Furnace size | L945×D510×H2400mm | ||||||

| Recommended heating rate | ≤10℃/min | ||||||

Control system |

| 1. Weighing sensor range: 300g; | |||||

Equipment details |

|

|

| ||||

Vacuum degree: ≤10Pa | |||||||

Pressure measurement and monitoring |

| The mechanical pressure gauge with damping oil is used to make the pressure fluctuation produce damping and reduce the pointer swinging back and forth. | |||||

gas supply system |

| Built-in gas mass flowmeter, including two gas switching and flow size control. | |||||

net weight | 220KG(excluding vacuum pump and water cooling circulator) | ||||||

Cautions | 1. When the furnace temperature of the equipment is ≥300℃, do not open the furnace to avoid damage; | ||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable components such as furnace tubes and seals). | ||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

Configuration

| Equipment introduction:

| ||||||

Model | NBD-TGA1100-80TD2ZY5L | ||||||

main function | 1. In the process of heating, constant temperature or cooling, the quality of the sample can be automatically recorded with the change curve of temperature, vacuum, gas flow and time; | ||||||

Electrical Spec | AC220V 4.5KW | ||||||

Tmax | 1150 ℃ | ||||||

Temp Accuracy | ±1℃ | ||||||

thermocouple | Type K thermocouple 420mm | ||||||

heating-zone size | φ150*430mm single heating-zone dual control | ||||||

Furnace tube material | 310s Stainless steel tube/quartz (interchangeable) | ||||||

| Load cell range | 300g | ||||||

| precision | Within 0.03g | ||||||

| Weight of wire and crucible | Approx.30g | ||||||

| Crucible material&size | Aluminum/stainless steel φ60*30mm | ||||||

| The sample can be weighed | 0~270g | ||||||

| Condensing collector volume and height adjustable range | 110ml can be moved up and down 60mm | ||||||

| Low temperature constant temperature reaction bath temperature control accuracy | ±1 degree volume 6L | ||||||

| Furnace size | L945×D510×H2400mm | ||||||

| Recommended heating rate | ≤10℃/min | ||||||

Control system |

| 1. Weighing sensor range: 300g; | |||||

Equipment details |

|

|

| ||||

Vacuum degree: ≤10Pa | |||||||

Pressure measurement and monitoring |

| The mechanical pressure gauge with damping oil is used to make the pressure fluctuation produce damping and reduce the pointer swinging back and forth. | |||||

gas supply system |

| Built-in gas mass flowmeter, including two gas switching and flow size control. | |||||

net weight | 220KG(excluding vacuum pump and water cooling circulator) | ||||||

Cautions | 1. When the furnace temperature of the equipment is ≥300℃, do not open the furnace to avoid damage; | ||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable components such as furnace tubes and seals). | ||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

| |||

| |||

推荐产品

CVD system O1200-XTID3F

High power PECVD system (Rotary Pendulum Vibration)

Vertical high-temperature tube furnace (Type I)

Intelligent muffle furnace(1700℃)

Well sintering furnace 1500/1700℃

Three temperature zone vertical tube furnace (fluidized bed FBCVD furnace)

1600℃microwave oven

Industrial vertical sintering furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China