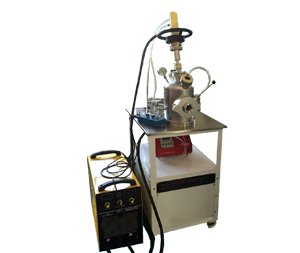

Vacuum arc melting furnace (non-consumable)

Release time: 2020-09-17 14:11:03 Number of views: 3495

The non-consumable arc melting furnace is mainly composed of arc melting vacuum chamber, arc gun, arc melting power supply, 4-station water-cooled copper crucible, turning manipulator, vacuum suction casting device, magnetic stirring, working gas path, system pumping, vacuum measurement and electrical control system, installation machine and other parts.

Configuration

Parameters | 1. Limit vacuum: 5.0x10-4Pa;

| ||

Model | NBD-VAP3000-35 | ||

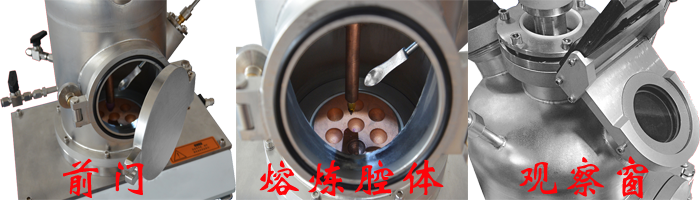

Arc melting vacuum chamber assembly | Vertical cylindrical vacuum chamber size: φ280mmX350mm, front door, double water-cooled structure, made of stainless steel, argon arc welding, surface electrochemical polishing treatment, the interface is sealed by metal washer or fluorine rubber ring.

| ||

Vacuum chamber top cover | 1. Arc gun interface 1 (arc melting cathode);

| ||

Arc smelting cathode | Water-cooled electric arc gun: 1 set (non-contact arc initiation) | ||

Water cooled copper crucible set | The arc melting anode has 4~6 stations, stations (30mm), and a melting degassing station (20mm); Melting sample weight (Fe calibration) : the maximum weight of the sample 50 grams; | ||

mechanical arm | For flipping alloy ingot under vacuum; The robot component has a water cooling device. | ||

Window and flange interface | 1. φ50 arc automatic protection device;

| ||

Vacuum acquisition | Molecular pump + mechanical pump | ||

Install frame and waterway | 1. High quality square steel profile (40mmX40mm X4) welded, coaming surface spray treatment; The machine surface is decorated with stainless steel skin; Four casters, can be fixed, movable;

| ||

Installation requirements | 1. Power supply 380V 50Hz power is greater than 10KW, fluctuation range: less than ± 6%, equipped with multiple wiring sockets;

| ||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

Large capacity muffle furnace 1700℃

0.35L melting furnace 1600℃

Universal testing machine with heating furnace (Type B)

Well type vacuum nitriding furnace

Intelligent Sintering Furnace AISF System (Automatic Intelligent Sintering Furnace)

Intelligent muffle furnace(1700℃)

Vertical tube furnace (saturated steam)

Well sintering furnace 1500/1700℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China