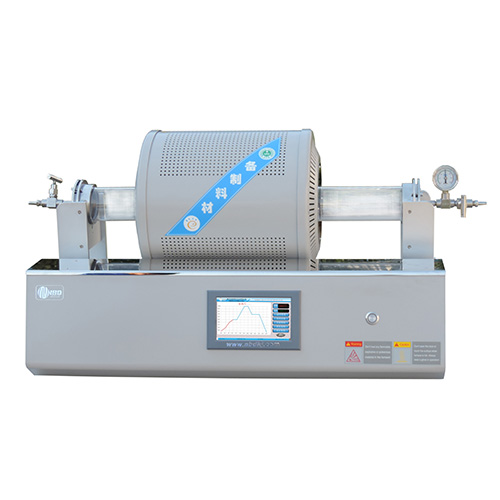

Slide rail rapid annealing furnace

Release time: 2020-04-11 16:16:52 Number of views: 4673

Equipment introduction:

The furnace can automatically move from side to side according to the setting requirements, and the moving speed can be manually adjusted, and the temperature field and rapid cooling can be changed at any time. After the furnace warms up to the set temperature on one side, it moves directly to the sample placement area on the other side, so as to realize rapid warming with the speed up to 140℃/min. After the completion of sintering, the furnace moves away from the sample placement area, so as to realize rapid cooling of the sample. The cooling rate of 300℃~1200℃ can reach 200℃ ~ 50℃/min.

Configuration

| 1. Double-layer steel structure; | |||||||||

Model | NBD-CMT1200-60TI | NBD-CMT1200-80TI | NBD-CMT1200-60TI+ | NBD-CMT1200-80IT+ | ||||||

Electrical Spec | AC220V 2.5KW | AC220V 4KW | ||||||||

Tmax | 1200 ℃ | |||||||||

Max working temps. | 1100 ℃ | |||||||||

Heating rate | ≤ 20 ℃/min | |||||||||

Length of heating zone | 200mm | 400mm | ||||||||

Tube size | Φ60*1000mm | Φ80*1000mm | Φ60*1400mm | Φ80*1400mm | ||||||

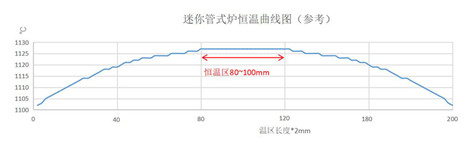

Temperature field distribution |

| As shown in the figure: This is the temperature zone diagram of the equipment | ||||||||

Control system |

| 1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; graphical interface, 7 inch true color touch screen input, intelligent man-machine dialogue mode, non-linear pattern temperature correction; leakage protection and so on. | ||||||||

Temp Accuracy | +/- 1 ℃ | |||||||||

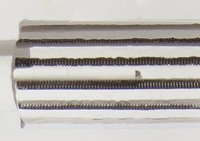

Heating element |

| Mo-doped Fe-Cr-Al alloy | ||||||||

Sealing system |

|

|

| |||||||

Vacuum degree: ≤10Pa (mechanical pump) | ||||||||||

Pressure measurement and monitoring |

| Mechanical pressure gauge with damping oil can prevent damage to the gauge pointer. | ||||||||

Gas supply system |

| Float flowmeter control, integration with equipment, convenient control, leakage test has been carried out before leaving the factory. | ||||||||

Net weight | 40KG | 50KG | ||||||||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; to prevent damage to the equipment caused by excessive pressure; pressure reducing valve must be installed on the cylinder. It is recommended to choose a small pressure reducing valve for test, and the measuring range of the valve is 0.01MPa-0.15MPa, which will be more accurate and safe in use. vacuum state, the pressure in the furnace tube and atmospheric pressure, maintain in the state of atmospheric pressure; the flange end of the furnace tube. If it is necessary to close the air valve to heat the sample, always pay attention to the indicator of the pressure gauge. If the absolute pressure gauge reading is greater than 0.15MPa, the exhaust valve must be opened immediately to prevent accidents (such as furnace pipe rupture, flanges flying out, etc.). | |||||||||

Service | 1 year warranty with lifetime support (The warranty does not include consumable parts, such as furnace tubes and O-rings). | |||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

| |||

| |||

推荐产品

Vacuum graphite heating furnace

Vertical high-temperature tube furnace (Type I)

Meltblowout cloth nozzle anaerobic cleaning furnace 1200℃

High temperature vertical quenching furnace

Lift type large capacity sintering furnace

High vacuum atmosphere muffle furnace

High temperature vertical rapid pyrolysis furnace

Open type high flux four-channel tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China