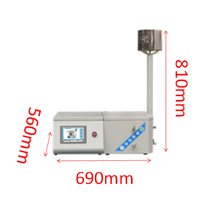

Mini hydrogen reduction furnace

Release time: 2020-4-10 23:50:33 Number of views: 4073

|

|

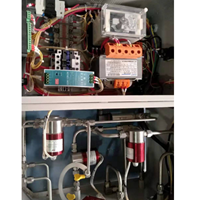

Equipment introduction: This equipment through the pressure detection of the furnace tube, to provide safety protection functions such as cutting off gas, cooling, can also be discharged flammable tail gas ignition treatment, and equipped with dual ignition protection, to ensure that the exhaust gas can be fully burned. With the use of tubular furnace can also be the furnace tube gas automatic cleaning replacement.

|

||

|

|

|

|

|

|

|

|||

Configuration

|

|

1. Automatic circulation vacuum cleaning and air supply; |

||

|

Model |

NBD-2AQD |

||

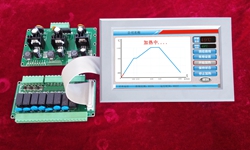

| Control system |

|

Corrosion-resistant stainless steel pipe or Teflon (optional) |

|

|

size of interface |

1/4"Double sleeve joint |

||

|

pipeline pressure |

-0.1-0.15MPa |

||

|

Net weight |

20KG |

||

|

Cautions |

1. Ensure that the absolute pressure in the pipeline is less than 0.15MPa; |

||

|

Service |

1 year warranty with lifetime support (consumable parts not included). |

||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|

||

|

|

|

|

|

|

|

Equipment introduction: This equipment through the pressure detection of the furnace tube, to provide safety protection functions such as cutting off gas, cooling, can also be discharged flammable tail gas ignition treatment, and equipped with dual ignition protection, to ensure that the exhaust gas can be fully burned. With the use of tubular furnace can also be the furnace tube gas automatic cleaning replacement.

|

||

|

|

|

|

|

|

|

|||

Configuration

|

|

1. Automatic circulation vacuum cleaning and air supply; |

||

|

Model |

NBD-2AQD |

||

| Control system |

|

Corrosion-resistant stainless steel pipe or Teflon (optional) |

|

|

size of interface |

1/4"Double sleeve joint |

||

|

pipeline pressure |

-0.1-0.15MPa |

||

|

Net weight |

20KG |

||

|

Cautions |

1. Ensure that the absolute pressure in the pipeline is less than 0.15MPa; |

||

|

Service |

1 year warranty with lifetime support (consumable parts not included). |

||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|

||

|

|

|

|

|

推荐产品

1500℃ large capacity muffle furnace

Universal testing machine with heating furnace (Type A)

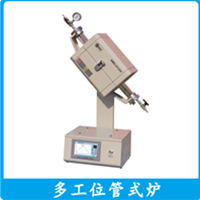

Hydrogen reduction furnace

Open Mini Rotary Stove

In situ observation of molten salt electroplating furnace

Three temperature zone vertical tube furnace (fluidized bed FBCVD furnace)

Anaerobic molten salt electroplating furnace

Split type five sided heating box furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China