High magnetic induction quenching furnace

Release time: 2018-11-13 13:55:53 Number of views: 4091

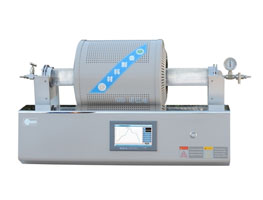

High-frequency induction heating furnace uses a high frequency alternating current to flow to a conductor (usually copper tube) that is curled into a ring, resulting in a magnetic beam, the metal is placed in it, the magnetic beam will pass through the metal body, and generate a pit current (rotating current) in the direction of the magnetic beam, which generates heat under the influence of the pit current. Thus, the heated object such as metal can be heated in a non-contact state. At this time, the characteristics of the pit current are concentrated induction heating on the object close to the coil, which is stronger on the surface of the object and weaker inside, and use this principle to concentrate heating in the necessary place of the heated body to achieve instant heating effect, thus making the production and workload relatively improved. The product is used for heating, melting or quenching of magnetic conductive materials in ultra-high frequency magnetic field or vacuum or atmosphere, which can open atmosphere and vacuum.

High-frequency induction heating furnace uses a high frequency alternating current to flow to a conductor (usually copper tube) that is curled into a ring, resulting in a magnetic beam, the metal is placed in it, the magnetic beam will pass through the metal body, and generate a pit current (rotating current) in the direction of the magnetic beam, which generates heat under the influence of the pit current. Thus, the heated object such as metal can be heated in a non-contact state. At this time, the characteristics of the pit current are concentrated induction heating on the object close to the coil, which is stronger on the surface of the object and weaker inside, and use this principle to concentrate heating in the necessary place of the heated body to achieve instant heating effect, thus making the production and workload relatively improved. The product is used for heating, melting or quenching of magnetic conductive materials in ultra-high frequency magnetic field or vacuum or atmosphere, which can open atmosphere and vacuum.

output power | 6KW | cooling water | 0.2Mpa, 2 L/min |

oscillation frequency | 300KHZ | duty cycle | 80% |

rated current | 5A-30A | volume | 580×250×500mm |

output power | 6KW | cooling water | 0.2Mpa, 2 L/min |

Technical parameter

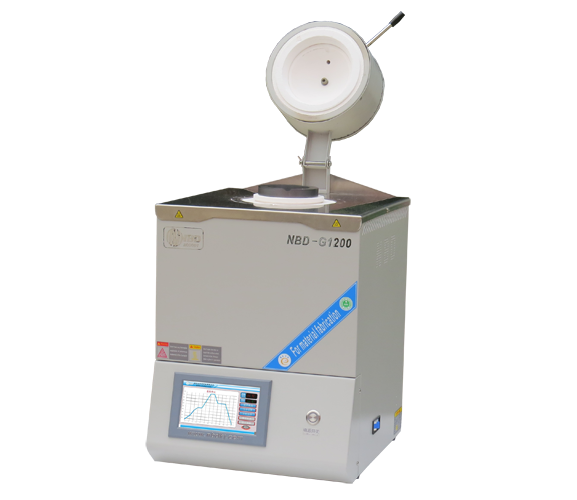

※ Specification: NBD-VAIP

※ Touch screen size: 7"

※ Power supply: AC220V 50HZ

※ Rated power: ≤6KW

※ Sensor type: infrared temperature measurement

※ Maximum temperature: 1200℃

※ Quartz cavity size: 30* 200/50 *200

※ Length of heating zone: 20mm

※ Ultra-high frequency magnetic field power supply; 300kHZ

※ Coil can glide automatically;

※ PID control, can manually adjust the current;

※ Can be vacuumed or ventilated atmosphere

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

Hydrogen reduction furnace with smooth bore

0.45L melting furnace 1200℃

Rotary pendulum oxidation furnace (silicon nitride tube)

1500 ℃ (80L) ultra large capacity box furnace

Large caliber intelligent tube furnace 1200℃

CMT furnace sliding rail tube furnace 1200℃

Universal testing machine with heating furnace (Type A)

Intelligent muffle furnace(1700℃)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China