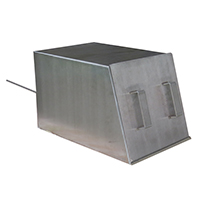

Intelligent muffle furnace (12L)1200℃

Release time: 2017-11-15 22:37:11 Number of views: 20843

Equipment introduction:

The flat design of this equipment not only greatly improves the proportion of space, but also separates the heating system and control unit reasonably and does not interfere with each other, which can ensure that the electric heating element and the whole circuit system keep safe and reliable working state in the high temperature environment. Simplified classic design process, multi-layer alumina fiber sintering furnace (so that the life of the furnace several times longer), using touch screen control, man-machine dialogue, barrier-free communication, so that the operation is easier.

Configuration details

| Equipment features: 1. The furnace chamber volume is moderately sized, suitable for various material heat treatment processes; 2. Uses advanced technology to manufacture refractory insulation materials, resulting in low heat loss and effectively reducing the power consumption of the equipment; 3. Modular structure, durable and easy to maintain; 4. Equipped with an exhaust chimney on the furnace roof, effectively removing volatiles generated during the sintering process; 5. Touchscreen operation, intuitively displaying temperature curves. | ||

Product Model | NBD-M1200-30TI(B型) | ||

Tmax | 1200℃ | ||

Rated power | 7KW | ||

Sensor Type | K type thermocouple | ||

Long-term operating temperature range | 300~1150℃ | ||

heating rate | 1℃/H-20℃/Min | ||

Furnace dimensions | W300*H300*D300mm | ||

| External dimensions | L860*H650*W670mm | ||

Control system |

| 1. NBD-101E embedded operating system with interchangeable English and Chinese graphical interface, 7-inch true color touch screen input, intelligent human-machine dialogue mode, non-linear temperature correction; 2. Can store up to 15 curves, each curve can be set with 30 segments of "time-temperature" nodes, eliminating the time needed to repeatedly modify curves; 3. Features over-temperature alarm, open-circuit prompt, leakage protection functions; | |

Temperature accuracy | +/- 1℃ | ||

Heating element |

| Mo-doped Fe-Cr-Al alloy | |

Atmosphere Protection Box (Optional) |  | The atmosphere protection box creates and maintains a specific atmospheric environment to protect materials during heating from oxidation, contamination, or adverse reactions with other components in the air (customizable size) | |

Net weight | Approximately120KG | ||

Equipment usage precautions | 1. When the equipment furnace temperature is ≥300°C, do not open the furnace to avoid injury; | ||

Service Support | 1-year warranty, lifetime support provided (warranty does not include consumable parts)。 | ||

Disclaimer: The product descriptions on this site (including product images, descriptions, and technical parameters) are for reference only. There may be discrepancies between the stated content and actual situations due to untimely updates. Please contact our customer service personnel for confirmation. Information provided on this site does not constitute any offer or promise. Nobadi Company periodically improves and modifies any information on the website without further notice.

推荐产品

Multi channel gas self-control controller

Split pit furnace for glove box

3-way mass gas proportioner

Clean-type top hat furnace

Anti-corrosion mini chamber furnace

(non) metal evaporation purification system

Molten salt furnace for glove box

Vertical tube Furnace (LT1700-80TI)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China