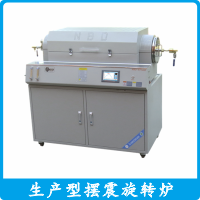

Large caliber intelligent tube furnace 1200℃

Release time: 2017-11-15 14:39:51 Number of views: 7825

Equipment introduction:

Large-caliber intelligent tube furnace is specially developed and manufactured for large parts or batch heat treatment production, mainly used in LED phosphor, substrate materials, battery materials production and other industries. The furnace tube is made of high purity quartz with large diameter, which can be used in both atmosphere and vacuum. Intelligent PID fuzzy control and multi-point temperature measurement are adopted to ensure the uniformity of temperature in the furnace.

Configuration

| 1. Oversized pipe diameter, ultra-long temperature zone, multi-point temperature control to ensure uniform distribution of equipment temperature; | |||||||||||||

Model | NBD-T1200-152T2 | NBD-T1200-152T3 | NBD-T1200-215T3 | |||||||||||

Electrical Spec | AC380V 10KW | AC380V 15KW | AC380V 24KW | |||||||||||

Tmax | 1200 ℃ | |||||||||||||

Max working temps. | 1100 ℃ | |||||||||||||

Heating rate | ≤20 ℃/min | |||||||||||||

Heating length | 600mm | 1100mm | 1100mm | |||||||||||

Tube size | Φ152*1200mm | Φ152*1650mm | Φ215*1660mm | |||||||||||

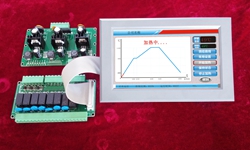

Control system |

| 1.NBD-101E embedded operating system Chinese and English interchangeable graphical interface, 7 inch true color touch screen input, intelligent man-machine dialogue mode, non-linear pattern temperature correction; | ||||||||||||

Temp Accuracy | +/- 1 ℃ | |||||||||||||

Heating element |

| High purity silicon carbon rods | ||||||||||||

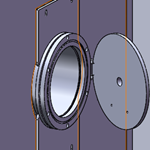

Sealing system |

|

|

| |||||||||||

Vacuum degree: ≤10Pa (mechanical pump) | ||||||||||||||

Pressure measurement & monitoring |

| Using intelligent digital pressure gauge, you can accurately display the pressure value, but also can set the pressure size. With high precision and high stability solenoid valve, the pressure inside the furnace can be effectively kept in a stable state. In addition, the equipment is equipped with a backup pressure protection system, which is more safe and reliable. | ||||||||||||

Gas supply system | Float flowmeter is used to control the flow rate of gas, integrated with the equipment, and the leakage test has been carried out before leaving the factory. | |||||||||||||

Net weight | 85KG | 105KG | 215KHG | |||||||||||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | |||||||||||||

Service | 1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). | |||||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

Bottom-loading sintering furnace

Anaerobic hot dip plating (quenching) system

Universal testing machine with heating furnace (Type A)

Blast drying oven (galvanized)

Horizontal silent ball mill mixer

Two float proportioners

Epitaxial furnace exhaust gas purifier

well type furnace G1200-15TI

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China