Eight temperature zone rotating inclined tube furnace

Release time: 2025-10-31 19:23:45 Number of views: 10

The automated rotating inclined eight temperature zone tube furnace is a high-end experimental and production equipment that integrates mechanical motion, precise temperature control, and atmosphere management, especially suitable for scenarios that require uniform heating and complex processes. Product features include one click operation from feeding to discharging, secondary feeding without damaging the atmosphere and environment, custom tilt angle, material transportation without damaging the process environment, and uniform temperature in the factory.

| Equipment features:

| |

Device Name | Rotating inclined tube furnace | |

Specification Model | NBD-RT1200-80OTP8DFY-N | |

power supply | AC380V 50HZ | |

rated power | 25KW | |

Number of temperature zones | Single temperature eight control | |

sensor type | K-type thermocouple with a diameter of 2 * 420mm | |

Tmax | 1150℃ | |

Long term working temperature | 1100℃ | |

Recommended heating rate | ≤10℃/min | |

Size of furnace temperature zone | Φ 150 * 2400 (8 300 temperature zones) mm | |

Tilt angle of furnace body | -1.5°~5° (Hand cranked screw lifting mechanism with 300 turns is 1°) | |

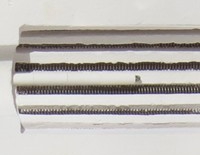

Furnace tube specifications | Quartz tube with concave points, diameter 100*3200*5mm | |

Furnace tube rotation speed | 0.1-6rpm/min(adjustable) | |

Capacity of inlet and outlet tanks | 5L | |

Flow meter type | 2-channel float flowmeter: 0.3-3L/min, 0.5-8L/min | |

oxygen analyzer | Measurement range: 0-1000PPM Measurement accuracy: ≤± 2% FS

| |

Measurement range: 0-1000PPM Measurement accuracy: ≤± 2% FS | DRV16 KF25joint | |

furnace body dimensions | Length 4000 * Height 2440 * Depth 930mm | |

Furnace weight | 约800KG | |

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

heating element | | Alloy resistance wire |

temperature accuracy | ±1℃ | |

Net weight | 约800KG | |

Equipment usage precautions |

1. When the furnace temperature of the equipment is ≥ 300 ℃, it is forbidden to open the furnace to avoid injury; | |

Service Support | One year limited warranty with lifetime support (warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). | |

Advanced Ceramics and Composite Materials

Chemical vapor infiltration (CVI): used for densification of carbon/carbon composites and ceramic matrix composites (CMC). The temperature gradient can be established in the eight temperature zone, and rotation ensures sufficient and uniform contact between the precursor gas and the fiber preform, significantly improving the density efficiency and material properties.

Uniform sintering: Rotational sintering is performed on high-purity oxide and nitride ceramic powders to prevent agglomeration and obtain ceramic products with high density and uniform performance.

new energy materials

Positive electrode material for lithium-ion batteries:

Continuous gradient sintering: Using eight temperature zones to simulate multi-stage sintering process, achieving full process control from preheating, reaction to cooling.

Surface coating: During the sintering process of the main material, coating elements (such as Al, Zr) are introduced through a secondary feeding system to achieve uniform coating under rotation and tilt, thereby improving the cycle life.

Solid electrolyte: perform gradient sintering to optimize grain boundary structure and improve ion conductivity.

Semiconductors and Two Dimensional Materials

CVD growth of two-dimensional materials: growth of graphene, molybdenum disulfide (MoS ₂), boron nitride (h-BN), etc.

Eight temperature zones: precise control of the temperature in the reaction, growth, and cooling zones.

Rotation: evenly heats and exposes the substrate to airflow, greatly improving the uniformity and consistency of the film.

Tilt: The influence of airflow angle on growth morphology can be studied.

Semiconductor annealing: multi-step, highly uniform annealing treatment of wafers or epitaxial wafers.

Metallurgy and Special Alloys

Reactive metal melting: Melting easily oxidizable metals such as titanium, zirconium, hafnium, etc. under vacuum or inert atmosphere, and rotating to promote component homogenization.

Directional solidification: By precisely controlling the temperature gradient (eight temperature zones) and furnace tilt angle, single crystal or columnar crystal growth is achieved, which is used for key components such as aircraft engine blades.

Processing of amorphous/microcrystalline alloy strip: Continuously annealing the quenched strip and rotating it to ensure uniform processing.

Nanomaterials and Catalysts

Nanoparticle synthesis: High temperature sintering and agglomeration of nanoparticles are prevented by rotation, and continuous production can be achieved by tilting.

Catalyst activation and regeneration: High temperature treatment of the catalyst under controlled atmosphere, rotating to ensure that each particle is fully activated.

Research and Frontier Exploration

Multi step chemical reaction: Complete the entire process of "pretreatment → main reaction → post-treatment" in one furnace, and control the movement of materials through tilting and rotation.

Research on the behavior of materials under dynamic conditions: investigating the effects of mechanical movements such as rotation and tilt on material phase transition, sintering, and reaction kinetics.

Simulating space or special environments: Tilt angles can be used to simulate heat and mass transfer processes in microgravity or specific directions.

推荐产品

Mini Fluidised Bed Vertical Tube Furnace

Microwave high temp muffle furnace

Cooling circulator

Ultrasonic Atomization CVD System

glass tempering furnace

Extended heating zone CVD slide tube type furnace

Roll to roll two-dimensional material preparation system

Large scale multi temperature zone vacuum tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China