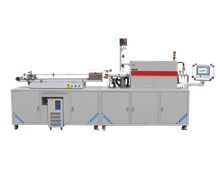

Large caliber (12 inch) uniform temperature diffusion furnac

Release time: 2025-10-23 00:27:53 Number of views: 28

|

Core features of the equipment

|

|

|

Device Name |

Large caliber vacuum diffusion furnace |

|

|

Specification Model |

NBD-T1200-400T5D4ZY-435 |

|

|

power supply |

AC380V 50HZ |

|

|

rated power |

65KW |

|

|

Number of temperature zones |

Single temperature five control |

|

|

temperature control accuracy |

±1℃ |

|

|

sensor type |

K-type thermocouple with a diameter of 1 * 250mm |

|

|

Tmax |

1200℃ |

|

|

Long term working temperature |

1100℃ |

|

|

Recommended heating rate |

≤20℃/min |

|

|

Size of furnace temperature zone |

Φ460*1625mm |

|

|

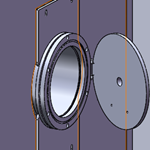

Furnace tube specifications |

quartz tubeφ400*2400*5mm |

|

|

Mass flow controller |

S500 2000SCCM with a diameter of 6.35 and a 2-meter double card sleeve. Fluorine rubber sealed nitrogen calibration for the short wire

|

|

|

Constant voltage control range |

100-90000Pa |

|

|

Air inlet and outlet interface |

Air inlet: Double card sleeve with a diameter of 6.35

|

|

|

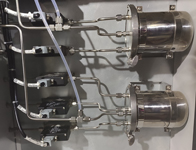

vacuum pump |

DRV60 KF40 three-phase |

|

|

Furnace body size |

Length 3080 (right bracket fully open, length 3750) * Height 1838 * Depth 880mm |

|

|

Heating chamber |

|

Insulation materials: crystal fibers, etc

|

|

control system |

|

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

|

heating element |

|

|

|

|

|

Vacuum degree: ≤ 10Pa (mechanical pump) |

|

gas supply system |

|

Using a mass flow meter to control gas flow rate, integrated with the equipment; |

|

temperature accuracy |

±1℃ |

|

|

Net weight |

About 800KG |

|

|

Equipment usage precautions |

11. Asbestos gloves must be worn when collecting samples, and quartz devices should be carefully broken when using them;

|

|

|

Service Support |

一Annual limited warranty, providing lifetime support (warranty scope does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). |

|

推荐产品

Automatic hydrogen reduction furnace Type II

Vertical double tube sintering furnace

High Flux Intelligent Chamber Furnace

PECVD Plasma Chemical Vapor Deposition System

Vacuum arc melting furnace (non-consumable)

Microwave high temp muffle furnace

High pressure tube furnace (single head 1200°C)

Ion sputtering device

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China