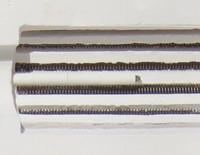

High throughput eight channel tubular furnace

Release time: 2025-10-22 22:41:01 Number of views: 23

High throughput heat treatment equipment with a honeycomb design that integrates eight separate tube furnaces. By saving user space, eight sets of experiments under different conditions (such as temperature and atmosphere) can be conducted simultaneously, or eight repeated experiments can be conducted on the same process, greatly improving research and development efficiency and data reliability. All operations and monitoring can be done on one interface, without the need to shuttle and set up between multiple devices; All process parameters and process data can be stored, exported, and analyzed uniformly for easy data management. Very suitable for fields that require high-throughput experiments or small batch parallel production。

| Equipment features:

| |

Device Name | High throughput heat treatment equipment | |

Specification Model | LT1200-50TI-8G2F | |

power supply | AC380V 50HZ | |

rated power | 20KW | |

sensor type | K-type thermocouple with a diameter of 1 * 350mm | |

Tmax | 1200℃ | |

Long term working temperature | 1150℃ | |

Recommended heating rate | ≤10℃/min | |

Number of temperature zones | Number of temperature zones | |

Size of furnace temperature zone | Φ80*400mm | |

Furnace tube material and size | 8 quartz tubes with a diameter of 50 * 800mm | |

Each furnace tube is supplied with two gas channels | Float flowmeter 20-200ml/min

| |

vacuum unit | Vacuum pump: KF25 interface Molecular pump: CF100 interface

| |

Furnace body size | Length 920 * Height 1475 * Depth 1970mm | |

control systemcontrol system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

加热元件 | | 合金电阻丝 |

heating element

|   | The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃.The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃.The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃. |

| Pressure measurement and monitoringPressure measurement and monitoring |   | Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance. Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance. |

temperature accuracy | ±1℃ | |

Net weight | About 420KG | |

Equipment usage precautions |

1. When the furnace temperature of the equipment is ≥ 300 ℃, it is forbidden to open the furnace to avoid injury; | |

Service Support | One year limited warranty with lifetime support (warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). | |

推荐产品

Molten salt furnace for glove box

Automatic feed anti deposition pyrolysis furnace

Well type melting furnace 0.45L1200℃

Vertical tube furnace (saturated steam)

well-type crucible melting furnace 0.1L 1200℃

Automatic hydrogen making machine H1000

High pressure and high vacuum rotary pendulum sintering furnace

PECVD Plasma Chemical Vapor Deposition System

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China