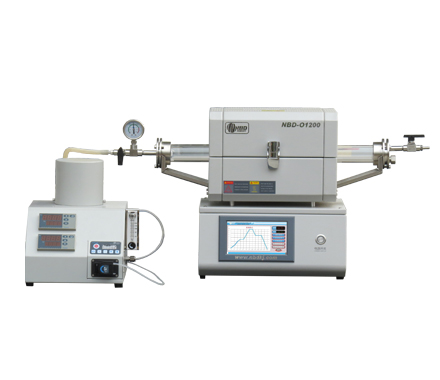

Box type electric stack high-temperature sintering furnace

Release time: 2025-10-13 21:22:58 Number of views: 2

Box type stack high-temperature sintering furnace integrates pressure control system and high-temperature heating equipment. Heating part: The furnace lining is made of vacuum formed high-purity alumina lightweight material, and resistance wires are used as heating elements. The pressure part adopts a high-precision pressure sensing system, achieving precise control from 0 to 5000N. It can perfectly meet the final high-temperature heat treatment requirements for solid oxide fuel cell stacks or their core components. This process is called "co sintering" and is the core manufacturing process that ensures the structural integrity, performance stability, and long-term lifespan of the fuel cell stack

|

Equipment features:

|

|

|

Device Name |

Box type electric stack high-temperature sintering furnace |

|

|

Device Model |

NBD-RYM30-50TIY20T |

|

|

rated power |

15KW |

|

|

rated voltage |

AC380V 50/60HZ |

|

|

Tmax |

1200℃ |

|

|

rated temperature |

1000℃ |

|

|

Recommended heating rate |

10℃/min |

|

|

furnace size |

400*400*400mm |

|

|

Dimensions (length x width x height) |

200*900*1850(Base 300 is detachable) |

|

|

temperature control accuracy |

±1℃ |

|

|

heating element |

resistance wire |

|

|

Heating element connection method |

triangle |

|

|

control system |

|

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

|

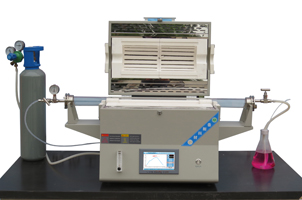

Gas supply system |

|

采用浮子流量计控制气体流速,与设备集成为一体,且出厂前已进行漏气测试工作。 |

|

Weakly corrosive gas preheater

|

|

The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃。 |

|

temperature accuracy |

+/- 1℃ |

|

|

Net weight |

About 400KG |

|

|

Equipment usage precautions |

When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure; |

|

|

Service Support |

One year limited warranty with lifetime support (warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). |

|

推荐产品

Vacuum storage cabinet

Industrial tubular furnace

Mini mixing sintering furnace

Steam generator for tube furnaces

Anaerobic purification electrolytic furnace

Heating-zone automatic tester

Single temperature zone tube furnace 1200℃

Vertical quenching furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China