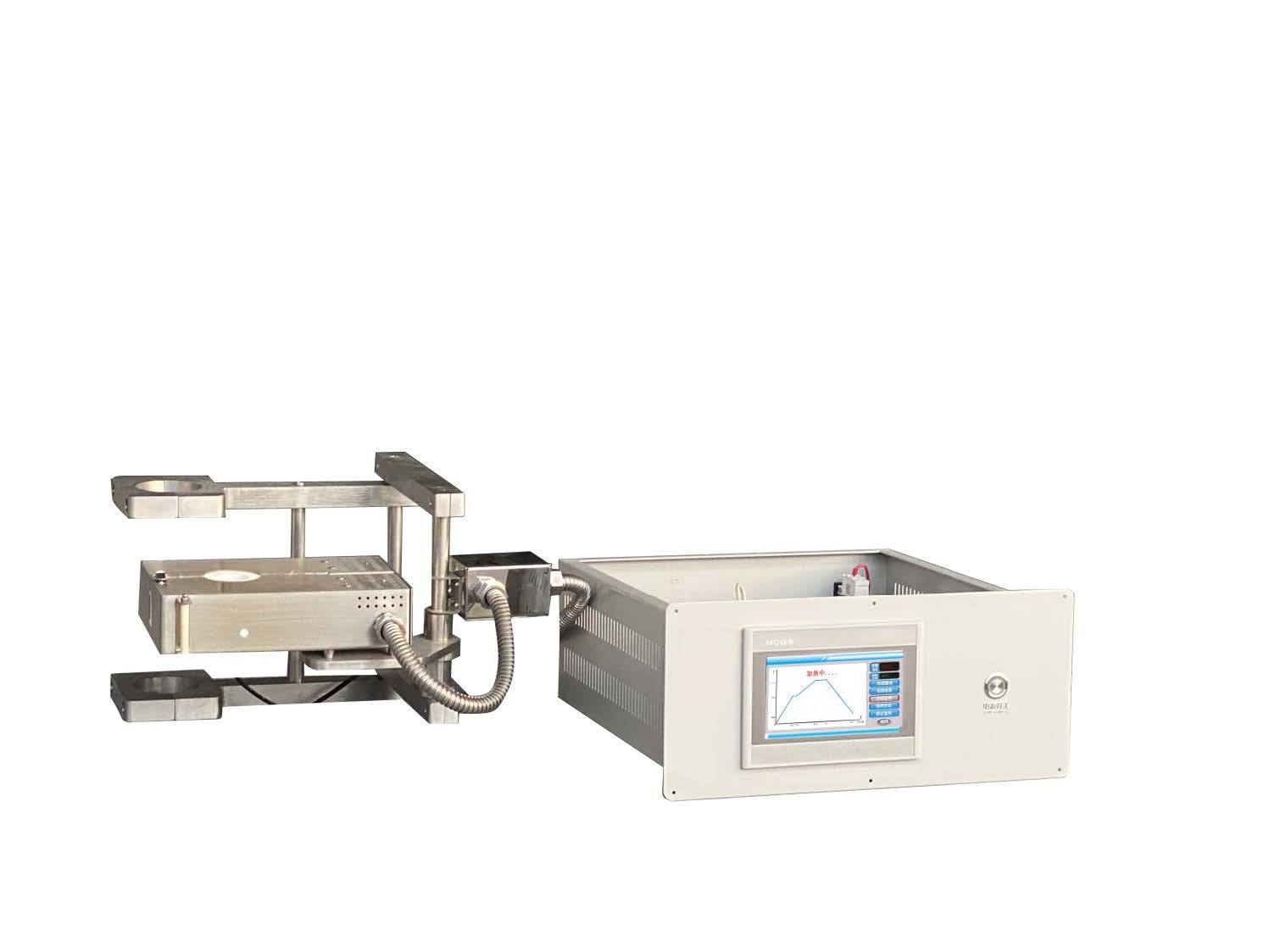

1400 ℃ universal testing machine with heating furnace

Release time: 2025-09-17 16:42:53 Number of views: 80

The universal testing machine is equipped with a heating furnace, which is an external high-temperature environment simulation device designed specifically for the Universal Testing Machine (UTM). Its core function is to provide a controllable high-temperature environment for the specimen, enabling the universal testing machine to perform mechanical property tests such as tensile, compressive, and bending on materials under high-temperature conditions, thereby obtaining key mechanical parameters of materials in real service environments (such as engine components, aerospace structures, high-temperature furnace components, etc.).

ious physical properties of the material.

|

This device is a customized heating system for universal testing machines, which uses high-purity silicon carbon rods as heating elements,

|

|

|

Device Name |

Open type heating furnace for 1400 ℃ universal testing machine |

|

|

Electrical specifications |

220V 50HZ 1KW |

|

|

heating power |

0.9KW |

|

|

heating element |

High purity double helix silicon carbon rod |

|

|

sensor type |

S-type thermocouple with a diameter of 4 * 85mm |

|

|

Tmax |

1400℃ |

|

|

Recommended heating rate |

≤10℃/min |

|

|

Reaction chamber material |

800 ℃ polycrystalline fiber |

|

|

Reaction chamber size |

Length 112 * Height 28 * Depth 100mm |

|

|

Dimensions of the upper and lower openings in the furnace |

φ35mm |

|

|

Front opening size |

8*28mm |

|

|

Furnace body size |

Length 184 * Height 65 * Depth 267mm (excluding bracket) |

|

|

control system |

|

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

|

temperature accuracy |

+/- 1℃ |

|

|

heating element |

|

High purity double helix silicon carbon rod |

|

Net weight |

About 14KG |

|

|

Equipment usage precautions |

1.When the furnace temperature of the equipment is ≥ 300 ℃, it is forbidden to open the furnace to avoid injury;

2. Minor cracks caused by continuous use of the furnace are a normal phenomenon and do not affect the normal use of the equipment;

|

|

|

Service Support |

One year limited warranty, providing lifetime support (the warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below) |

|

Metal materials: Test the tensile strength, yield strength, elastic modulus, elongation, etc. of high-temperature alloys, stainless steel, titanium alloys, aluminum alloys, etc. at high temperatures.

Ceramics and Composite Materials: Evaluating the High Temperature Mechanical Properties of Advanced Ceramics, Ceramic Ceramic Matrix Composites (CMC), and Carbon/Carbon Composite Materials.

Polymer materials: Study the performance changes of special engineering plastics and high-temperature resistant polymers near their glass transition temperature or melting point.

Research and standard testing: universities and research institutes conduct research on the high-temperature performance of materials; Enterprises conduct product certification and quality control (such as compliance with high-temperature tensile standards such as ASTM E21, ISO 783, etc.).

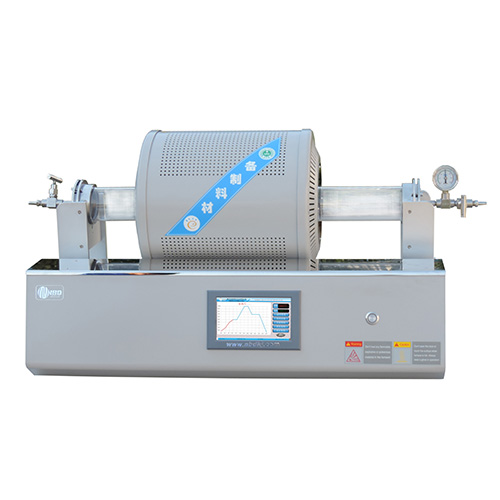

推荐产品

Slide rail rapid annealing furnace

1200°C Vacuum Atmosphere Chamber Furnace(27L)

Mesh belt brazing furnace

well-type crucible melting furnace 0.1L 1200℃

Battery Tester 5V100mA Quad Range (BT-2018R)

Ultrasonic atomizing CVD tube furnace

1200 ℃ CVD integrated machine

High temperature vacuum induction furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China