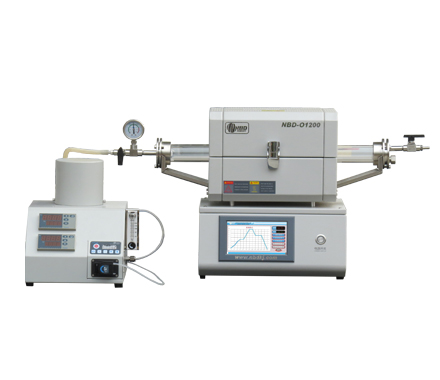

NBD-LTO1200-50T3D4Z

FBCVD fluidized bed tube furnace

Release time: 2025-09-03 20:02:31 Number of views: 109

Three temperature zone fluidized bed tube furnace High pressure fluidized bed tube furnace Quartz tube fluidized bed tube furnace Nickel based alloy tube fluidized bed tube furnace Vacuum fluidized bed tube furnace Continuous fluidized bed tube furnace Laboratory fluidized bed tube furnace Customized fluidized bed tube furnace

| Core features of the device:

| |

Device Name | FBCVD fluidized bed tube furnace | |

Specification Model | ||

power supply | Three phase 380V 50HZ | |

rated power | 9KW | |

heating element | Alloy resistance wire | |

Number of temperature zones | Three temperature zones | |

sensor type | K-type thermocouple with a diameter of 2 * 420mm | |

Furnace tube material and size | Variable diameter quartz tube: diameter 50- diameter 80 * 1300 * 3, side diameter 20 Variable diameter quartz sand core tube: φ 20- φ 40 * 450 (200 mesh sand core)

| |

Tmax | 1200℃ | |

rated temperature | 1100℃ | |

Recommended heating rate | ≤10℃/min | |

Temperature zone size and length | φ150*(300+300+300)mm | |

Four channel mass flow controller | Hydrogen gas: S500 1000SCCM with a diameter of 6.35 and a 2-meter double card sleeve. Fluorine rubber sealed nitrogen gas calibration

| |

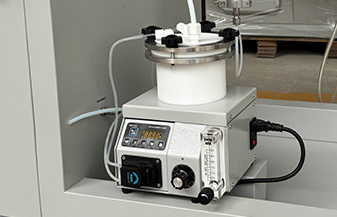

Atomizer | Rated power: 55W (including 35W atomizer and 20W peristaltic pump) Maximum flow rate of peristaltic pump: 11-13ml/min Float flowmeter: 0.3-3L/min Maximum volume of liquid storage tank: 360ml Atomized particle size: 5-10 μ m Atomization rate: 0.4ml/min (using pure water medium, with an intake rate of 1L/min at maximum power)

| |

Furnace body size | Length 1105 * Height 2370 * Depth 650mm | |

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

temperature accuracy | ±1℃ | |

heating element |

| Mo doped Fe Cr Al alloy |

Ultrasonic atomizer |  | The ultrasonic atomizer provides a gentle, efficient, and precise liquid phase introduction method for fluidized bed technology. It ensures sufficient and uniform contact between liquid and fluidized particles by generating small, uniform, and low-speed droplets, thus playing a key role in processes such as particle coating, material synthesis, granulation, cooling and humidity control. Its advantages of no blockage, easy control, and minimal disturbance to the fluidized state make it an indispensable core component in high-end fluidized bed equipment, significantly improving product quality and process stability. |

cyclone separator |  | Efficiently recover valuable solid materials and reduce losses. Purify process gases and protect downstream equipment, especially fans and heating systems. Maintain stable operation of fluidized bed to ensure process continuity. Meet environmental requirements and reduce dust emissions. Although it does not directly participate in heating or chemical reactions, its efficient separation performance is directly related to the operating efficiency, equipment life, product quality, and environmental compliance of the entire system. It is a key component to ensure the safe, stable, and long-term operation of fluidized bed tube furnaces. |

Pressure measurement and monitoring |   | Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance. |

Net weight | About 240KG | |

Equipment usage precautions |

1. When the furnace temperature of the equipment is ≥ 300 ℃, it is forbidden to open the furnace to avoid injury;

| |

Service Support | One year limited warranty, providing lifetime support (the warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below) | |

推荐产品

Pilot scale molten salt electroplating furnace

CVD系统O1200-MINI-G3Z

High pressure tube furnace

Steam generator for tube furnaces

Six temperature zone tube furnace (corrosion-resistant silicon carbide furnace tube)

Zirconia crystallizing furnace

CVDO1200-XTIG3Z

High-temperature physical property testing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China