Split molten salt electrolytic furnace

Release time: 2025-08-31 00:19:32 Number of views: 112

Molten salt furnaces are the key bridge between electrical energy and highly active metal/material production. It becomes an irreplaceable technology for industrial production of metals such as aluminum, magnesium, sodium and rare earth by virtue of its advantage in treating substances that cannot be electrolyzed in aqueous solution (such as Al ³Mg ²). At the same time, it plays an increasingly important role in the frontier areas of sustainable nuclear energy and advanced material preparation. The equipment is characterized by high temperature, high corrosion, high current and high safety, embodying the high combination of electrochemical engineering and high temperature material technology.

| Easy operation and maintenance

| |

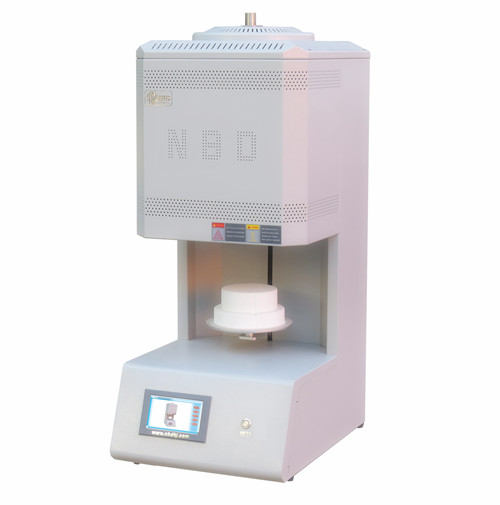

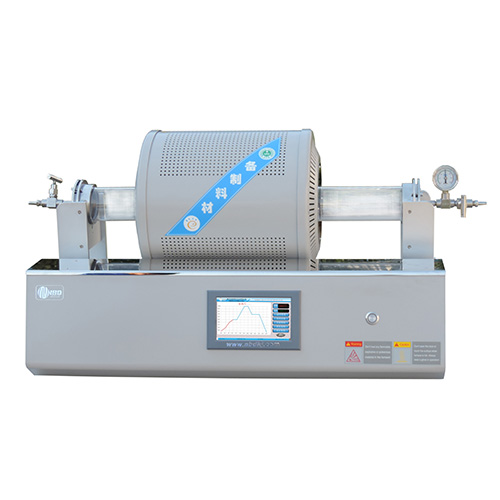

Equipment name | Split molten salt electrolytic furnace | |

Specification and model | NBD-LTO1700-80TP2F9L-N | |

Power supply | AC220V 50HZ | |

Rated power | 6.7KW | |

Heating element, heating element | Type 1800 hot bending high-purity silicon molybdenum rod | |

Type of sensor | Furnace temperature control: B-type thermocouple φ 8 * 150mm

| |

Tmax | 1700℃ | |

Long-term operating temperature | ≤1650℃ | |

Recommended heating rate | ≤10℃/min | |

Recommended heating rate | Corundum pipe Φ 80 * 800mm | |

Furnace temperature zone size | L140*H200*D140mm | |

Material and dimension of seal chamber | Acrylic tube φ 350 * 10 * 420mm | |

Float flow meter | Two ways0.5-8L/min | |

Cold cooling circulating pump | Cold water chamber volume 9L Power 2KW | |

Cold water chamber volume 9L Power 2KW | Mm (upper and lower limit positions can be adjusted) | |

Maximum lift stroke of upper chamber | Mm (upper and lower limit positions can be adjusted) | |

Furnace body size | Equipment body: length 570 * height 2175 * depth 975mm

| |

control system |

| 1. Sintering process curve setting: the setting curve is displayed dynamically, multiple process curves can be pre-stored for equipment sintering, and each process curve can be set freely;

|

Temperature accuracy | +/- 1℃ | |

Weight of furnace body (including electric cabinet) | Approximately 167KG | |

Precautions for equipment use |

When the equipment is used, the reading of the absolute pressure gauge shall not be greater than 0.15MPa to prevent equipment damage caused by excessive pressure; | |

Service support | One year limited warranty with lifetime support (Consumable parts, such as processing tubes and O-rings, are not covered by this warranty. Please order replacement parts from the relevant products below.) | |

Aluminum production: Alumina - cryolite (AlO - NaHall-H routing process) system electrolytically fused by Hall-H process is the production mode of more than 95% of primary aluminum in the world.

Magnesium production: electrolytic anhydrous magnesium chloride (MgClmolten salt to produce magnesium metal.

Sodium and lithium production: Electrolytically melt sodium chloride (NaCl) or lithium chloride (LiCl) to prepare active metals.

Production of rare earth metals: Electrolytically melt chloride or fluoride salt to prepare rare earth metals such as lanthanum, cerium and neodymium.

Nuclear and Nuclear Fuel Cycle:

Spent fuel reprocessing: in dry reprocessing, molten salt electrolysis technology is used to separate and recover actinides such as uranium and plutonium from molten chloride salt and separate them from fission products.

Preparation of nuclear material: production of high-purity zirconium, hafnium and other anti-corrosion nuclear materials.

High-purity and special material preparation:

High-purity titanium/zirconium/hafnium: Direct electrolysis of its oxide (in CaClmolten salt) by means of FFC Cambridge method is a promising low-cost and high-purity preparation method.

Purification of refractory metals: used for refining metals such as tungsten and molybdenum.

Electrodeposition of functional materials: Electrodeposition of special coatings or composites in molten salts.

Production of Chemicals:

Production of strong oxidants such as perchlorate (KClO) and persulfate.

推荐产品

Experimental hydrogen reduction furnace

Large capacity bottom-loading furnace

Constant voltage control system

Slide rail rapid annealing furnace

Automatic hydrogen reduction furnace Type II

Split type five sided heating box furnace

Vacuum well furnace

Split vertical ingot melting furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China