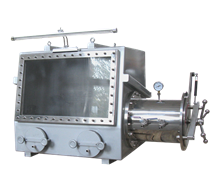

High-temperature physical property testing furnace

Release time: 2025-08-31 00:00:42 Number of views: 151

High-temperature physical property testing furnace is an integrated platform integrating heating, temperature control, environmental control and precision measurement systems. Its core principle is to apply specific physical stimuli (such as force, current, magnetic field, etc.) to the material sample under a controlled high temperature environment, and accurately measure its response, so as to calculate various physical properties of the material.

| 1、 Core design objectives

| |

Device Name | Split type high-temperature physical property testing furnace | |

Specification Model | NBD-LTO1700-80TP2F9L-N | |

power supply | AC220V 50HZ | |

额定功率 | 6.7KW | |

heating element | 1800 type hot bent high-purity silicon molybdenum rod | |

sensor type | Furnace temperature control: B-type thermocouple with a diameter of 8 * 150mm

| |

Tmax | 1700℃ | |

Long term working temperature | ≤1650℃ | |

Recommended heating rate | ≤10℃/min | |

Type and size of furnace tube | Corundum tube, diameter 80 * 800mm | |

Size of furnace temperature zone | Length 140 * Height 200 * Depth 140mm | |

Sealing chamber material and size | Acrylic pipe with a diameter of 350 * 10 * 420mm | |

float flow meter | Two channels of 0.5-8L/min | |

Low temperature cooling circulation pump | Cold water chamber capacity 9L, power 2KW | |

Maximum lifting stroke of electrode | 100mm (adjustable upper and lower limit positions) | |

Maximum lifting stroke of upper chamber | 510mm (adjustable upper and lower limit positions) | |

Furnace body size | Equipment body: length 570 * height 2175 * depth 975mm

| |

Furnace weight (including electrical control box) | 约167KG | |

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

temperature accuracy | +/- 1℃ | |

Furnace weight (including electrical control box) | About 167KG | |

Equipment usage precautions |

When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure; | |

Service Support | One year limited warranty, providing lifetime support (the warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below) | |

推荐产品

glass tempering furnace

Titanium rod annealing furnace

Liquid Vapor Phase Generator (Type II)

Large caliber intelligent tube furnace 1200℃

Rotary pendulum oxidation furnace (silicon nitride tube)

12L intelligent box furnace

Pilot scale molten salt electroplating furnace

TGB-2 Vacuum glove box

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China