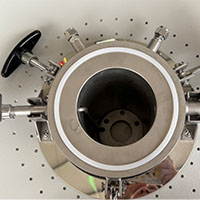

Vacuum molten salt electroplating furnace

Release time: 2025-07-15 19:34:17 Number of views: 77

A vacuum molten salt electroplating furnace is a device specifically designed for electroplating or chemical plating using molten salt as a medium in a vacuum environment. This technology combines the advantages of vacuum technology and molten salt electrolysis, enabling high-quality metal deposition under strictly controlled conditions, and is suitable for preparing high-performance, high-purity coating materials. This device is widely used in aerospace, electronics, new energy, new materials and other fields, especially in surface treatment that requires special properties such as corrosion resistance, wear resistance, and conductivity.

| main features

| ||

Equipment name | Vacuum molten salt electroplating furnace | ||

Specification and model | NBD-G1200-10TPIDF5LR-50A15V | ||

power supply | 220V 50HZ | ||

rated power | 3KW | ||

precision | ±1℃ | ||

heating element | Alloy heating wire | ||

Temperature control thermocouple | K-type thermocouple with a diameter of 2 * 350mm | ||

temperature thermocouple | K-type right angle thermocouple with a diameter of 8 * 100mm+450mm (aviation plug) | ||

Tmax | 1150℃ | ||

Reactor size | Φ 120 * 368mm (effective sample space is approximately Φ 78 * 160mm) | ||

DC POWER SUPPLY | LDX-K1080D(800W/10V/80A)

| ||

Long term working temperature | 1100℃ | ||

Recommended heating rate | ≤10℃/min | ||

rotameter | 20-200ml/min | ||

Size of furnace temperature zone | Φ150*200mm | ||

Furnace body size | Length 760 * Height 900 * Depth 610mm | ||

Furnace weight | 约90KG | ||

control system | | 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

| |

| Equipment Details |   | reaction kettle | |

Weakly corrosive gas preheater

|   | The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃. | |

Equipment usage precautions | Minor cracks caused by continuous use of the furnace are a normal phenomenon and do not affect the normal use of the equipment; | ||

| Service Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and seals). | ||

推荐产品

Vacuum molten salt electrolysis furnace

Small CVD system

Small tube furnace 1500/1700 ℃

Expansion coefficient tester

Horizontal vacuum atmosphere furnace

Open type high flux four-channel tube furnace

Dual-channel K-type digital thermometer

Automatic feed anti deposition pyrolysis furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China