MiNi tube furnace 1200℃

Release time: 2017-11-15 14:25:21 Number of views: 12063

Equipment introduction:

Mini tube furnace is an experimental equipment for heat treatment of various materials. The main industries are rare earth preparation, electronic lighting, crystal annealing, bioceramics, electronic ceramics, special alloys, magnetic materials, precision casting, etc., mainly used in vacuum sintering, atmosphere protection sintering, vacuum coating, CVD experiment, substance composition measurement and other occasions.

Configuration

| 1. Double-layer air-cooled structure; | ||||||

Model | NBD-O1200-25TI-80 | NBD-O1200-50TI-80 | |||||

Electrical Spec | AC220V 1.2KW | ||||||

Tmax | 1200 ℃ | ||||||

Max working temps. | 1100 ℃ | ||||||

Heating rate | ≤ 20 ℃/min | ||||||

Heating length | 200mm | ||||||

Tube size | Φ25*600mm | Φ50*600mm | |||||

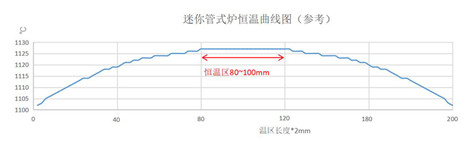

Temperature field distribution |

| As shown in the figure: This is the temperature zone curve of the equipment (size of constant temperature zone: 100mm) | |||||

Control system |

| 1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; | |||||

Temp Accuracy | +/- 1 ℃ | ||||||

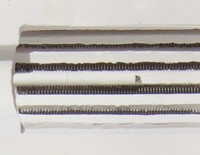

Heating element |

| Mo-doped Fe-Cr-Al alloy | |||||

Sealing system |

|

|

| ||||

Vacuum degree: ≤10Pa (mechanical pump) | |||||||

Pressure measurement & monitoring |

| The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. | |||||

Net weight | 20KG | ||||||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | ||||||

Service | 1 year warranty with lifetime support (The warranty does not include consumable parts, such as furnace tubes and sealing rings). | ||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

Six temperature zone tube furnace (corrosion-resistant silicon carbide furnace tube)

3-way float gas proportioner

1500℃ large capacity muffle furnace

Split pit furnace for glove box

Cooling circulator

Full bridge crystallizing furnace

Split vertical ingot melting furnace

Uniform temperature heating platform

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China