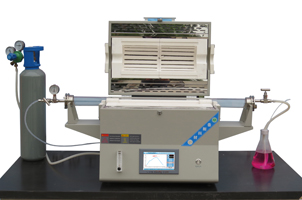

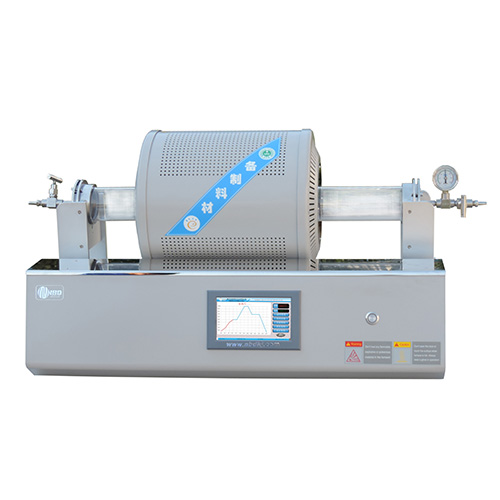

Openable vertical tube furnace 1200℃

Release time: 2017-09-28 16:51:18 Number of views: 5287

Equipment Introduction:

The vertical tube furnace adopts a structural design of vertical placement of furnace tubes and annular distribution of furnace heating wires, which can be applied to quenching, annealing, tempering heat treatment of small steel parts, as well as vertical CVD coating. The equipment can operate in atmospheric and vacuum conditions, and can also be used as a regular tube furnace, suitable for universities, laboratories, research institutes, and other units.

Equipment Features: 1. The heating wire is ring-shaped and distributed inside the furnace chamber, surrounding the furnace tube 360 degrees, improving the temperature uniformity within the furnace; 2. High-purity Al2O3 fiber fire-resistant insulation material provides excellent insulation performance, effectively reducing the power consumption of the equipment; 3. The furnace body adopts a double-layer air-cooling structural process, helping to reduce the surface temperature of the casing; 4. Intelligent PID fuzzy temperature control is used, with centralized control via a 7-inch touchscreen, allowing intuitive display of the "time-temperature" curve; | |||

Product Model | NBD-LT1200-100TI | ||

Electrical specifications | AC220V 2KW | ||

Tmax | 1200 ℃ (<1小时) | ||

Long term use temperature range | 300~1150℃ | ||

Heating rate range | ≤20℃/min | ||

Effective working size | Φ150*200mm | ||

Furnace tube size | Φ100*700mm | ||

Furnace body size | 700*1200*520mm(Long, high, and deep) | ||

Sample vessel | Nickel based porous plate production, interchangeable between 50 microns and 10 microns | ||

control system |

| 1. The NBD-101E embedded operating system features a graphical interface for exchanging Chinese and English, a 7-inch true color touch screen input, and an intelligent human-machine dialogue mode; | |

Temperature Accuracy | +/- 1℃ | ||

heating element |

| Resistance wire, circular heating, more uniform temperature, better sample sintering effect | |

SEALING SYSTEM |

|

| 1. Stainless steel flange; |

Vacuum degree: ≤ 10Pa (mechanical pump), if higher vacuum is required, our molecular pump unit can be used | |||

Pressure measurement and monitoring |

| Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance. | |

Vacuum vibrator chamber |

| Torque resonant spring, stainless steel sealed cavity | |

Equipment usage precautions | When using the equipment, the pressure inside the furnace tube should not exceed 0.125MPa (absolute pressure) to prevent equipment damage caused by excessive pressure; | ||

Service Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and sealing rings) | ||

推荐产品

2-way mass gas proportioner

Hydrogen reduction furnace with smooth bore

Plasma enhanced rotary PECVD system

Single temperature zone tube furnace 1200℃

4C vacuum pump

Slide rail rapid annealing furnace

Mini vacuum furnace for glove box

High pressure tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China