Location:Home > Product >

Large caliber (12 inch) uniform temperature diffusion furnac

Location:Home > Product >

Large caliber (12 inch) uniform temperature diffusion furnac

Add Time: 2025-10-23 View:36

The isothermal diffusion furnace is a high-precision and highly uniform horizontal tube type high-temperature furnace designed specifically for fields such as semiconductors, photovoltaics, and microelectronics. Its core goal is to provide an extremely uniform temperature and precise controllable atmosphere for heat treatment of silicon wafers, wafers or other substrates, in order to achieve high-quality key processes such as diffusion doping, oxidation, annealing, sintering, etc. The 'average t...

|

Core features of the equipment

|

|

|

Device Name |

Large caliber vacuum diffusion furnace |

|

|

Specification Model |

NBD-T1200-400T5D4ZY-435 |

|

|

power supply |

AC380V 50HZ |

|

|

rated power |

65KW |

|

|

Number of temperature zones |

Single temperature five control |

|

|

temperature control accuracy |

±1℃ |

|

|

sensor type |

K-type thermocouple with a diameter of 1 * 250mm |

|

|

Tmax |

1200℃ |

|

|

Long term working temperature |

1100℃ |

|

|

Recommended heating rate |

≤20℃/min |

|

|

Size of furnace temperature zone |

Φ460*1625mm |

|

|

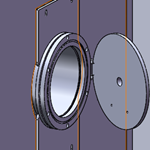

Furnace tube specifications |

quartz tubeφ400*2400*5mm |

|

|

Mass flow controller |

S500 2000SCCM with a diameter of 6.35 and a 2-meter double card sleeve. Fluorine rubber sealed nitrogen calibration for the short wire

|

|

|

Constant voltage control range |

100-90000Pa |

|

|

Air inlet and outlet interface |

Air inlet: Double card sleeve with a diameter of 6.35

|

|

|

vacuum pump |

DRV60 KF40 three-phase |

|

|

Furnace body size |

Length 3080 (right bracket fully open, length 3750) * Height 1838 * Depth 880mm |

|

|

Heating chamber |

|

Insulation materials: crystal fibers, etc

|

|

control system |

|

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

|

heating element |

|

|

|

|

|

Vacuum degree: ≤ 10Pa (mechanical pump) |

|

gas supply system |

|

Using a mass flow meter to control gas flow rate, integrated with the equipment; |

|

temperature accuracy |

±1℃ |

|

|

Net weight |

About 800KG |

|

|

Equipment usage precautions |

11. Asbestos gloves must be worn when collecting samples, and quartz devices should be carefully broken when using them;

|

|

|

Service Support |

一Annual limited warranty, providing lifetime support (warranty scope does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). |

|