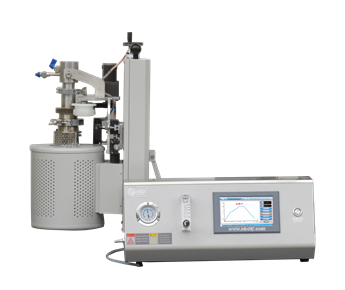

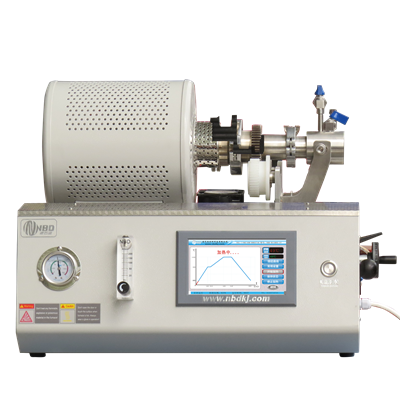

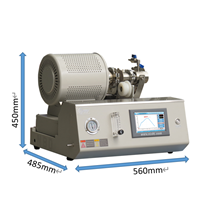

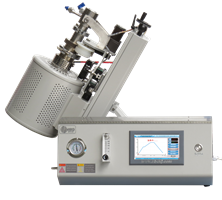

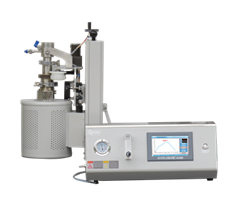

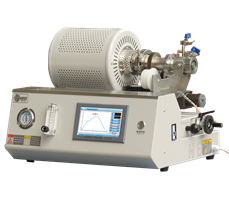

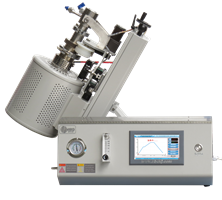

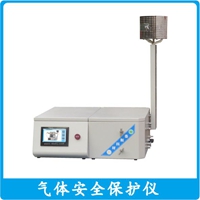

Mini mixing sintering furnace

Release time: 2022-4-24 16:02:36 Number of views: 1386

|

|

|

|

|

|

Configuration

|

|

1. Through constant rotation, the material can be heated and contact with the gas more fully and evenly; |

||||||

|

Model |

NBD-RT1200-50TI |

||||||

|

Electrical Spec |

AC220V 1.2KW |

||||||

|

Tmax |

1200 ℃ |

||||||

|

Max working temps. |

1150 ℃ |

||||||

|

Heating rate |

≤ 10 ℃/min |

||||||

|

Heating zone size |

φ80*100mm |

||||||

|

Tube size |

Φ50×220mm(One end is sealed ) |

||||||

|

Effective volume |

70ml (Tilt 90 degrees) 48ml (tilt 60 degrees) 33ml (Tilt 45 degrees) 17ml (Tilt 30 degrees)

|

Calculate the constant temperature zone according to the length of temperature zone 50 |

|||||

|

control system |

|

1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; |

|||||

|

Temp Accuracy |

+/- 1 ℃ |

||||||

|

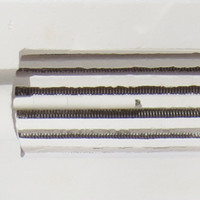

Heating element |

|

Mo-doped Fe-Cr-Al alloy |

|||||

|

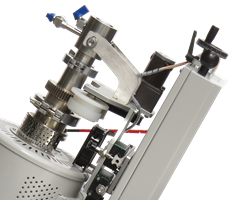

Equipment details |

|

|

|

||||

|

Vacuum degree: ≤10Pa (mechanical pump) |

|||||||

|

Pressure measurement and monitoring |

|

The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. |

|||||

|

净重 |

20KG |

||||||

|

设备使用注意事项 |

1. 设备炉膛温度≥300℃时,禁止打开炉膛,避免受到伤害; 2. 设备使用时,炉管内压力不得超过0.125MPa(绝对压力),以防止压力过大造成设备损坏; 3. 真空下使用时,设备使用温度不得超过800℃。

4. 供气钢瓶内部气压较高,向炉管内通入气体时,气瓶上必须安装减压阀,建议在选购试验用小压力减压阀,减压阀量程为0.01MPa-0.15MPa,使用时会更加精确安全。 5.当炉体温度高于1000℃时,炉管内不可处于真空状态,炉管内的气压需和大气压 相当,保持在常压状态; 6.高纯石英管的长时间使用温度≦1100℃ 7.加热的实验时,不建议关闭炉管法兰端的抽气阀和进气阀使用。若需要关闭气阀对样品加热,则需时刻关注压力表的示数,若绝对压力表读数大于0.15MPa,必须立刻打开排气端阀门,以防意外发生(如炉 管破裂,法兰飞出等) |

||||||

|

服务支持 |

1年质保,提供终身支持(保修范围内不包括易耗部件,例如炉管和密封圈等) |

||||||

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,诺巴迪公司不定期完善和修改网站任何信息,恕不另行通知。

相关产品

|

|

|

||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

Configuration

|

|

1. Through constant rotation, the material can be heated and contact with the gas more fully and evenly; |

||||||

|

Model |

NBD-RT1200-50TI |

||||||

|

Electrical Spec |

AC220V 1.2KW |

||||||

|

Tmax |

1200 ℃ |

||||||

|

Max working temps. |

1150 ℃ |

||||||

|

Heating rate |

≤ 10 ℃/min |

||||||

|

Heating zone size |

φ80*100mm |

||||||

|

Tube size |

Φ50×220mm(One end is sealed ) |

||||||

|

Effective volume |

70ml (Tilt 90 degrees) 48ml (tilt 60 degrees) 33ml (Tilt 45 degrees) 17ml (Tilt 30 degrees)

|

Calculate the constant temperature zone according to the length of temperature zone 50 |

|||||

|

control system |

|

1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; |

|||||

|

Temp Accuracy |

+/- 1 ℃ |

||||||

|

Heating element |

|

Mo-doped Fe-Cr-Al alloy |

|||||

|

Equipment details |

|

|

|

||||

|

Vacuum degree: ≤10Pa (mechanical pump) |

|||||||

|

Pressure measurement and monitoring |

|

The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. |

|||||

|

净重 |

20KG |

||||||

|

设备使用注意事项 |

1. 设备炉膛温度≥300℃时,禁止打开炉膛,避免受到伤害; 2. 设备使用时,炉管内压力不得超过0.125MPa(绝对压力),以防止压力过大造成设备损坏; 3. 真空下使用时,设备使用温度不得超过800℃。

4. 供气钢瓶内部气压较高,向炉管内通入气体时,气瓶上必须安装减压阀,建议在选购试验用小压力减压阀,减压阀量程为0.01MPa-0.15MPa,使用时会更加精确安全。 5.当炉体温度高于1000℃时,炉管内不可处于真空状态,炉管内的气压需和大气压 相当,保持在常压状态; 6.高纯石英管的长时间使用温度≦1100℃ 7.加热的实验时,不建议关闭炉管法兰端的抽气阀和进气阀使用。若需要关闭气阀对样品加热,则需时刻关注压力表的示数,若绝对压力表读数大于0.15MPa,必须立刻打开排气端阀门,以防意外发生(如炉 管破裂,法兰飞出等) |

||||||

|

服务支持 |

1年质保,提供终身支持(保修范围内不包括易耗部件,例如炉管和密封圈等) |

||||||

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,诺巴迪公司不定期完善和修改网站任何信息,恕不另行通知。

相关产品

|

|

|

||

|

|

|

|

|

推荐产品

NBD-103(B) Vacuum system

steam generator

Extended heating zone CVD slide tube type furnace

Anaerobic hot dip plating (quenching) system

Microwave high temp muffle furnace

Homogeneous oxidation diffusion furnace (Type I)

Vertical high-temperature tube furnace (Type I)

3C vacuum pump

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China