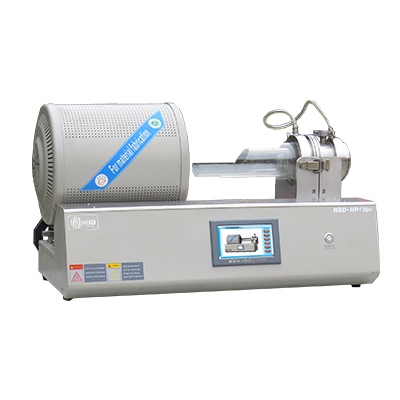

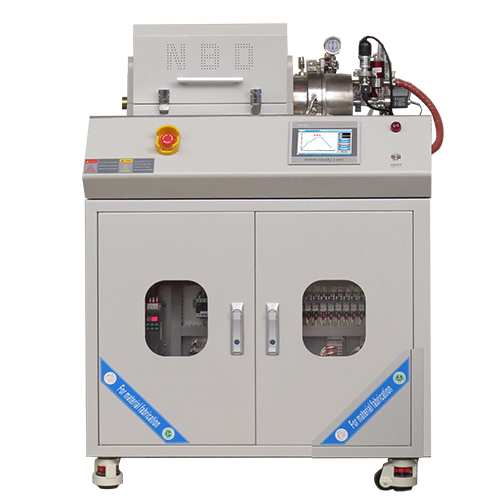

High temperature steam oxidation aging furnace

Test content

2) Conduct a corrosion performance test of no less than 10000 hours on the original coating heat pipe material and the irradiated coating material under different operating conditions (dry air and high temperature steam) (the oxidation time of the irradiated material is adjusted according to the irradiation depth, with the oxidation time not exceeding the irradiation depth as the standard). By comparing with each other, evaluate the service performance of various coating materials and clarify the influence and mechanism of material irradiation on oxidation behavior.

Long term antioxidant testing equipment and instruments

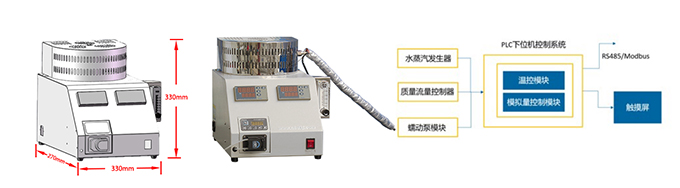

The above devices have the following systems and functions:

1) Heating system: using radiation heating or resistance heating, the heat pipe sample can be heated to 500-1000 ℃, and the length of the uniform temperature zone (within ± 5 ℃ of the target temperature) is not less than 20 cm.

2) Air drying room: The experiment of drying air uses standard gas cylinders filled with dry air for testing.

3) Steam chamber: The steam chamber requires sealing to prevent the entry of gas-phase impurities during the testing process.

4) Steam circuit: Use ultrapure water containing HCl to generate steam containing chloride ions, with an average steam flow rate range of 0.8~30mg/(cm2 · s) and a steam pressure equal to or slightly higher than atmospheric pressure, as shown in Figure 2.

thirty-two

2.3 Test Materials

Heat pipe/sheet: Heat pipe/sheet without coating and coated, with a length of 15-30mm. The sheet size is 10 * 15mm.

Sample quantity: The number of parallel samples should not be less than 3.

2.4.2 Long cycle high-temperature oxidation test

The specific experimental steps are as follows:

1) Sample cleaning: Organic solvents (such as ethanol) can be used for cleaning, and direct contact with the sample should be avoided after cleaning.

2) Measurement of sample size and weight: After the sample is dried, measure the length, outer diameter, wall thickness, and weight of each sample.

a) Length and width: The end face should be as flat as possible, at a 90 ° angle to the length direction, with a deviation of no more than ± 5 °, rounded to one decimal place, and measured in millimeters.

b) Outer diameter (pipe): When measuring, take the average of the maximum and minimum values, with two decimal places, in millimeters.

c) Thickness: rounded to two decimal places, in millimeters.

d) Weight: rounded to 0.1mg.

3) Sample installation: During the installation process, alumina or zirconia gaskets should be used to isolate the sample from the sample holder.

4) Steam chamber inflation and stable steam flow:

a) Dry air environment: At room temperature, introduce dry air from the gas cylinder into the quartz glass chamber. By adjusting the size of the gas flow meter, the flow rate of dry air entering the quartz glass chamber is ensured to be stable. At the same time, the chamber begins to heat up, reaching the target temperature (650 ℃, 700 ℃, 750 ℃) and maintaining stability.

b) High temperature steam environment: At room temperature, high-purity argon gas is filled into the steam chamber to eliminate air; Then steam is introduced into the steam chamber, which is generated by a steam generator. A certain concentration of HCl solution is used as the steam source to ensure that the high-temperature steam environment contains a certain concentration of chloride ions (with a chloride ion content range of 5ppb to 100ppb). Then the steam chamber begins to heat up, reaching the target temperature (650 ℃, 700 ℃, 750 ℃) and maintaining stability.

5) Sample oxidation: Under the premise of ensuring stable steam flow rate at the target temperature, conduct a high-temperature corrosion test for up to 10000 hours, with sampling periods of 100h, 300h, 500h, 1000h, 2500h, 5000h, 7500h, and 10000h.

6) Post oxidation detection: After reaching the target oxidation time, this stage of the experiment ends, and drying and weighing begin. The sample is dried by air cooling, and the weight of the sample is maintained at a minimum value during the drying process, and the drying is completed; Reduce the weight to approximately 0.1mg.