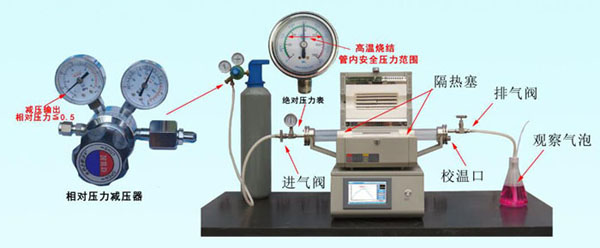

When the internal absolute pressure is greater than or equal to 0.1Mpa, open the exhaust valve completely. Adjust the flow, observe bubbles, and protect the atmosphere normally Below, 5~60 bubbles /min is appropriate;

a) The exhaust terminal is blocked due to pollution; (furnace shutdown cleaning) b) gas source loss; (Replace the gas cylinder)

Note: When the exhaust end is blocked, the furnace should be stopped and cleaned in time to prevent the furnace tube from being damaged;

4. When using high purity quartz furnace tube or corundum furnace tube at high temperature, the absolute pressure range in the furnace tube should be controlled in

0.05Mpa~0.15Mpa, so as not to cause damage to the furnace tube;

5. The actual temperature of the display temperature and the pattern point will be different at different sintering temperature points, and the true temperature of the pattern.

The degree can be checked online in real time by hand-held thermometer through the flange temperature hole.

6. Alkali metal ions K, Na, Li, Ca, Mg, etc. will cause crystallization damage to quartz furnace tube at high temperature;

7. The sintering procedure is set in the unit of minutes in the way of "initial temperature -- sintering time -- target temperature"

After setting the sintering curve, enter "END" in the setting period.